Why my needles are breaking on my embroidery machine

Why my needles are breaking on my embroidery machine

A machine will break needles every time if you do not pay attention. You need to observe and pay attention to the causes so that your needle does not break again.

A common issue with embroidery machines is that the needle breaks when you are stitching the fabric. Needles can break in the embroidery machine because of the tension applied.

This article explains w to correct this problem and keep your machine working efficiently.

Here are a few reasons why your needle breaks:

- You don’t use the appropriate needle for each fabric, eg: needles for jeans/jeans, elastic fabrics?

- Do you use Schmetz needles?

- Check if the needle is well placed (flat side to the back and inserted all the way).

- Never pull on the fabric while sewing.

- Isn’t the fabric too thick? If you can’t easily pierce the fabric with a pin, then the machine won’t either.

Does the needle break only when sewing backwards?

- Then the needle is too fine or the fabric is too thick.

- Put the needle up first, then you can sew backwards.

Always use the appropriate needle for each fabric, eg needles for jeans/jeans, elastic fabrics.

Never pull the fabric while sewing. Never sew backwards at full speed. Check if the needle is well placed (99% = flat side to the back).

Hitting

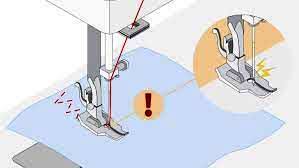

The needle only breaks when it hits something it can’t go through, so it must always be positioned correctly To be in line with the needle plate, you must take special care when pulling the fabric. This will ensure that the needle doesn’t dislodge or fall out of alignment.

If the needle breaks for some reason, then it is essential to collect all the pieces of the broken needle to prevent them from slipping through the mechanism and spoiling the entire machine.

Low speed or too much noise

The most normal thing is that these mishaps occur because the machine needs lubrication or slight basic maintenance adjustments.

The seams are crooked

This can happen for two reasons: the presser foot is not applying the proper pressure and the fabric is not aligned as it should.

When the fabric is not alligned, most people make a mistake a try to pull it by hand, which could cause the needle to break.

The fabric slips or resists

There is a homemade trick to prevent fabrics from being unruly and that is to put a bit of masking tape at the base of the presser foot.

The thread gets tangled under the fabric

Also called “bird’s nest”, it arises when there is no tension on the needle thread to pull the thread from the bobbin.

You can correct it by reinserting the machine and following the thread groove carefully.

You have to ensure that the thread is fully engaged in the tension mechanism so that needle won’t break.

Upper thread break

Upper thread breakage is one of the most common jams in sewing machines and can result in broken needles.

Lower thread breakage

When the thread that gives us problems is the lower one, the first thing we should do is check that the thread is not caught in the bobbin capsule.

Maybe another cause could be the winding. If it is not done correctly or is so full that it does not turn well can also cause needle breakage.