Almost item that has spinning parts contains gears. Automobile engines and gearboxes both have numerous gears. A VCR is filled with gears if you ever open it up and take a peek inside.

Wind-up and pendulum clocks have several gears, especially if they have bells or chimes. If your home’s power meter has a see-through cover, you may be able to see that it has 10 to 15 gears. Everywhere that engines and motors

rotating motion, gears are present.

Understanding the Concept of Gear Ratio

It is simple to understand the concept of the gear ratio once you are familiar with the concept of circle radius. Recall that a circle’s circumference is determined by multiplying its diameter by pi, where pi is equal to 3.14159. Therefore, a circle or gear with a diameter of 1 inch has a circumference of 3,14159 inches.

Consider rolling a second circle in the same way, but with a diameter of 0.635 inches (1.27 inches / 2). It requires two full revolutions to span the same 4-inch line because its diameter is half that of the circle being displayed.

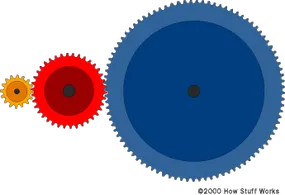

This explains why a 2:1 gear ratio exists between two gears, each of which is half as big as the other. To go the same distance as the larger gear’s single spin, the smaller gear must turn twice.

In the real world, teeth are present on the majority of gears. Teeth have the following three advantages:

· They prevent the sliding of the gears. Axles connected by gears are thus always perfectly synchronized with one another.

· They make it possible to calculate gear ratios precisely. Just add up the number of teeth on the two gears and divide it. The gear ratio between these two gears is 3:1 if one gear has 60 teeth and the other has 20.

· They design it such that minute differences between two gears’ diameter and circumference are meaningless. The number of teeth determines the gear ratio even though the diameters are slightly off.

The Function of Gear Ratio

The main purpose of a gear ratio is to increase speed while decreasing torque, and vice versa. Higher gear ratios won’t make your car move since early acceleration needs more torque than horsepower.

However, as speed is more important than torque when traveling on the highway, smaller gear ratios are not helpful. Therefore, it is possible to think of the gear ratio as a compromise between torque and speed.

Other Gear Uses

Your best choice, if you want to attain a high gear ratio, is the worm gear. In a worm gear, a threaded shaft comes into contact with the gear teeth. The gear advances one tooth for each full revolution of the shaft. In a very small size, like a windshield wiper, a gear with forty teeth has a 40:1 gear ratio.

Another device that frequently uses worm gears is a mechanical odometer.

Planetary Gears: An Introduction

The uses for gears are countless. One type of specialized gear train is the planetary gear train. The problem outlined below is addressed by planetary gears. Let’s say you want to output and input that rotate in the same direction at a 6:1 gear ratio.

Intriguing planetary gear sets can provide a variety of gear ratios depending on which gear is used as the input, which gear is used as the output, and which gear is stationary.

For instance, if we link the output shaft to the planet carrier while holding the ring gear stationary and the input is the sun gear, we will obtain a different gear ratio.

You can rearrange everything once more, but keep the sun gear stationary and link the output of the planet carrier to the input of the ring gear this time. This would lead to a 1.17:1 gear reduction.

An automated transmission makes varied gear ratios by using planetary gear sets and clutches and brake bands to control inputs and outputs and keep various components of the gearset stationary.

Conclusion:

It is clear from the aforementioned cases that planetary gears are incredibly effective. To get the most out of these gears, however, it’s essential to work with a reputable and high-quality planetary gear manufacturer like Wanfu Group. To discover more right away, get in touch with our team of professionals!

Understanding the Concept of Gear Ratio

It is simple to understand the concept of the gear ratio once you are familiar with the concept of circle radius. Recall that a circle’s circumference is determined by multiplying its diameter by pi, where pi is equal to 3.14159. Therefore, a circle or gear with a diameter of 1 inch has a circumference of 3,14159 inches.

Consider rolling a second circle in the same way, but with a diameter of 0.635 inches (1.27 inches / 2). It requires two full revolutions to span the same 4-inch line because its diameter is half that of the circle being displayed.

This explains why a 2:1 gear ratio exists between two gears, each of which is half as big as the other. To go the same distance as the larger gear’s single spin, the smaller gear must turn twice.

In the real world, teeth are present on the majority of gears. Teeth have the following three advantages:

· They prevent the sliding of the gears. Axles connected by gears are thus always perfectly synchronized with one another.

· They make it possible to calculate gear ratios precisely. Just add up the number of teeth on the two gears and divide it. The gear ratio between these two gears is 3:1 if one gear has 60 teeth and the other has 20.

· They design it such that minute differences between two gears’ diameter and circumference are meaningless. The number of teeth determines the gear ratio even though the diameters are slightly off.

It is simple to understand the concept of the gear ratio once you are familiar with the concept of circle radius. Recall that a circle’s circumference is determined by multiplying its diameter by pi, where pi is equal to 3.14159. Therefore, a circle or gear with a diameter of 1 inch has a circumference of 3,14159 inches.

Consider rolling a second circle in the same way, but with a diameter of 0.635 inches (1.27 inches / 2). It requires two full revolutions to span the same 4-inch line because its diameter is half that of the circle being displayed.