What is Laser Wafer Dicing

Laser wafer dicing is a technique that is widely used in the semiconductor industry. This technique is considerably more expensive than using a blade saw method. It requires high-precision laser beams to cut thin layers of silicon. However, its advantages make it worth considering if you need to make a high-quality chip.

Process

Wafer dicing involves the cutting of the silicon wafers with a diamond-tip blade, which moves across the crystal plane of the silicon wafer. The cutting process generates a small amount of residual stress and does not require the use of coolants. This process can produce a variety of shapes, such as squares and rectangles.

The first step involves focusing the laser beam at specific points on the wafer surface. The laser beam travels across the wafer at a speed of about 300 mm per second. This laser beam creates internal cracks in the silicon but does not damage the wafer’s front and back surfaces.

The second step involves cutting the wafer’s surface by means of a laser beam. Pulsed and continuous wave lasers are used for most applications. Both beams of light can have high-intensity levels. This is important because some devices can be sensitive to scattered laser light. Once the laser beam is focused, the wafer is cut in the scribed pattern.

Plasma dicing has several advantages over blade dicing. The plasma dicing process requires less silicon and more dicing lanes. This makes it a faster and more efficient process when die sizes get smaller. It also eliminates guard rings and allows a more flexible die shape. Additionally, it does not require linear dicing paths, which helps increase the die count.

In addition to the plasma dicing process, there are other technologies available. For example, Plasma Diving uses a gas called SF6 to create a shallow trench in the wafer. The gas is then applied to the wafer, causing the wafer to shrink. Afterward, the wafer is placed on a dicing frame.

In addition, laser wafer dicing produces internal heat that may pyrolyze the water-soluble resin. This can result in a crosslinking reaction. As a result, the crosslinked material remains on the wafer’s upper surface.

Technique

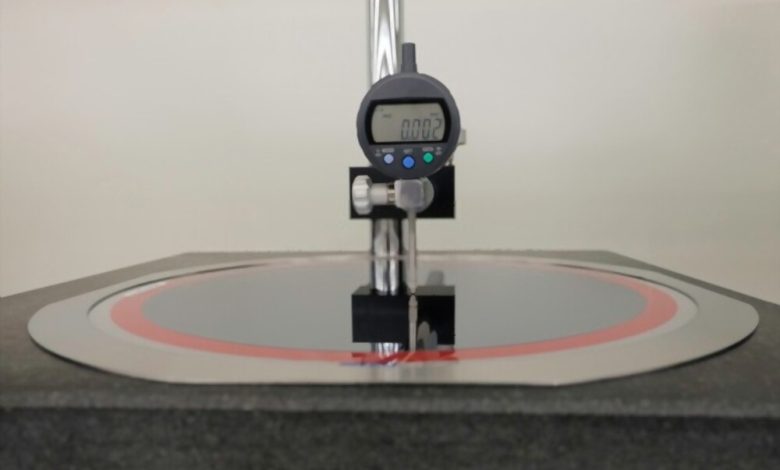

Laser wafer dicing is a technique for removing material from silicon wafers. This technique uses a die with a small diameter that can range from 35 mm (large) to 0.1 mm (small). The die is typically rectangular or square. The die is held in place using a mounting tape to minimize movement. Die handling equipment may also include a die bonder or sorter.

The stealth dicing technique is a highly advanced method for cutting wafers. It is an improved alternative to blade dicing. Also, it is capable of dicing thick wafers and is also water-efficient. It is capable of reducing water consumption by 622 tons a year.

The laser beam used to cut semiconductor wafers uses repetitive ON/OFF cycles. It is effective for cutting polygon and irregularly-shaped wafers and can be used to create microstructured devices. As the demand for semiconductor devices grows, mechanical wafer dicing techniques are reaching their limits. As a result, advances in power scaling have made it possible to produce reliable ultraviolet-wavelength lasers.

However, the blade technique may be too aggressive for thin silicon wafers. Another alternative is laser ablation, although it has its own problems. Laser ablation causes a microcrack or two in the wafer after the process. These microcracks will weaken the chip, making it less durable.

Cost

Laser wafer dicing systems can be expensive to purchase. The amount of money you spend will depend on how much dicing you need. You can look for companies that specialize in dicing systems, which will reduce your costs. For example, the Blackstar laser wafer dicing machine uses a high-power laser and Fantom-Width Laser Dicing Technology to split materials at the molecular level. This type of system allows for fast and high-speed dicing with high edge quality. Additionally, this type of machine can reduce the risks associated with power-hungry RF microdevices.

A laser wafer dicing system uses a high-powered UV DPSS laser to cut a thin silicon or DAF wafer. It uses proprietary processes to ensure that the chipping and damage are minimal. The process also uses scanning galvanometers to achieve high speeds. The speed increases as the wafers are thinner, with speeds up to 230 mm/s for 20um DAF and 50um silicon. Another benefit to laser wafer dicing is that no DI water is used. Additionally, laser diodes last for many years.

Chip makers are becoming increasingly concerned with the cost of thin silicon wafers, as they require less space and higher performance. Moreover, they are facing challenges with current methods of dicing, such as low throughput and yield. Xsil’s laser wafer dicing system provides higher yield, high throughput, and low consumable costs – all of which translate to higher profits.

Depending on the thickness of the wafer, the laser wafer dicing process can be expensive. High-power IR lasers, for instance, are more expensive and require higher pulse repetition rates to cut bridges. Green and UV lasers are also available, and they are both effective for dicing.

The Laser Wafer Dicing Machine Market Report provides detailed information on industry size, recent trends, and future growth. It also contains an analysis of the competitive landscape and key players. Also, it highlights the market size and segmentation data by company, type, and region. It also identifies opportunities and threats.

The cost of laser wafer dicing is one of the biggest concerns facing chip makers. Compared to conventional methods, laser dicing is faster, has no physical contact, and requires less space. However, it is not without its downsides. The process also generates heat, which can damage chip circuitry and degrade the mechanical strength of individual dies.

Competitive analysis

This market report provides a comprehensive analysis of the global Laser Wafer Dicing Machine market. The report focuses on different segments based on their revenue and production capacity. The report also provides insights into the growth of the market by geography and type of laser dicing system. For instance, the laser dicing segment is expected to grow at a 6.3% CAGR over the next seven years.

The main goals of laser wafer dicing are to minimize cracks and chippings, achieve the smoothest cutting track, and minimize lateral edge breaks. As a result, the method has been proven to be extremely effective for processing hard-brittle materials. However, the various parameters of a laser affect its results.

The Laser Wafer Dicing Machine market is examined in four regions. The first region is North America, which includes the United States and Canada. The second region includes China, India, and Korea. Finally, the third region is the Middle East, which includes Saudi Arabia, Egypt, Nigeria, and UAE.

The report includes profiles of key players in the industry. It also outlines their business strategies and SWOT analyses. The report also includes information on key developments in the last five years. It provides a detailed analysis of competitive dynamics in each region. It also provides information on public and private companies.

The report also provides information on regional growth and the competitive landscape of the global Laser Wafer Dicing Machine industry. It covers regional market size and volume for the major players. It also provides company profiles, SWOT analysis, and detailed revenue data. Listed below are key players in the global Laser Wafer Dicing Machine market.

The report also provides an analysis of the different market segments by product. It also provides an overview of the five competitive forces of the industry. This analysis will assist companies in making decisions regarding investment and product development strategies. The report also discusses the current COVID outbreak in the industry. It provide a SWOT analysis and PEST analysis of the market.

The report also includes Porter’s five forces analysis for the thin wafer processing equipment market. This analysis will help the reader determine the level of competition and market attractiveness in the industry.

Thanks for visiting renoarticle

Post Views: 497